Modulus of elasticity e 10 9 pa.

Belleville washer spring rate.

T represents the washer material thickness as well as the washer solid flat height.

Tensile stress σ 10 6 pa.

1 spring is considered to be 1 in parallel 1 in series.

These washers have smaller outside diameters than standard spring lock washers to fit neatly under socket head cap screws.

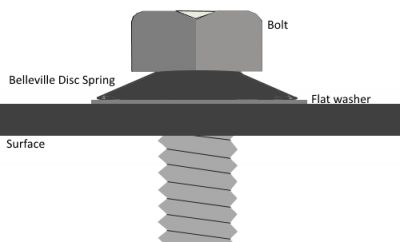

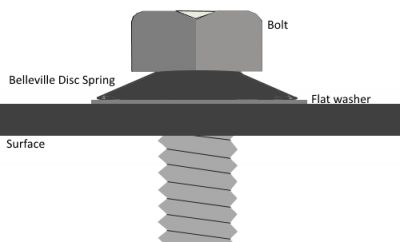

A belleville washer or disc spring is a conical shaped spring with an open center.

Belleville washers engineering data belleville washer stacking example.

Belleville spring washer coned disc spring and conical spring washer are all names for a type of spring that is a conically shaped disc that deflects flattens at a given rate.

Performance considerations a similar device is a wave washer.

Conical spring washers have a high spring rate resolve thermal expansion and can produce extremely high loads in a small area.

Spring inner diameter d0 2 r0 10 3 m.

Spring force f n.

888 426 6655 id represents the washer inside diameter.

So a 2 3 1 2 stack or since addition is commutative a 3 2 2 1 stack gives a spring constant of 3 7 that of a single washer.

The slight or aggressive conical shape gives the washer a spring characteristic and action.

K the spring constant of one washer.

Spring deflection f 10 3 m.

A belleville washer is a type of spring shaped like a washer it is the frusto conical shape that gives the washer its characteristic spring.

Belleville washers are typically used as springs where the spring action is used to apply a pre load or flexible quality to a bolted joint.

Spring outer diameter d 2 r 10 3 m.

Because belleville washers can bear a much larger load relative to its deflection rate than a coiled spring they are ideal for cushioning heavy loads with short motion.

The total spring coefficient for this group of belleville washers is calculated as below.

Od represents the washer.

A belleville spring or washer is formed into a conical or cone shaped geometry.

Belleville spring lock washers also known as conical washers these have a slightly cupped shape that gives them spring like flexibility to grip tighter than split and tooth lock washers.

This notation is needed for load calculations if n of springs in a stack then.

Spring stiffness k df df f f 10 3 n m.

N i the number of washers in the i th group.

This is a minimum measurement and reflects the bolt size that the washer will accommodate.

Spring thickness δ 10 3 m.

G the number of groups.